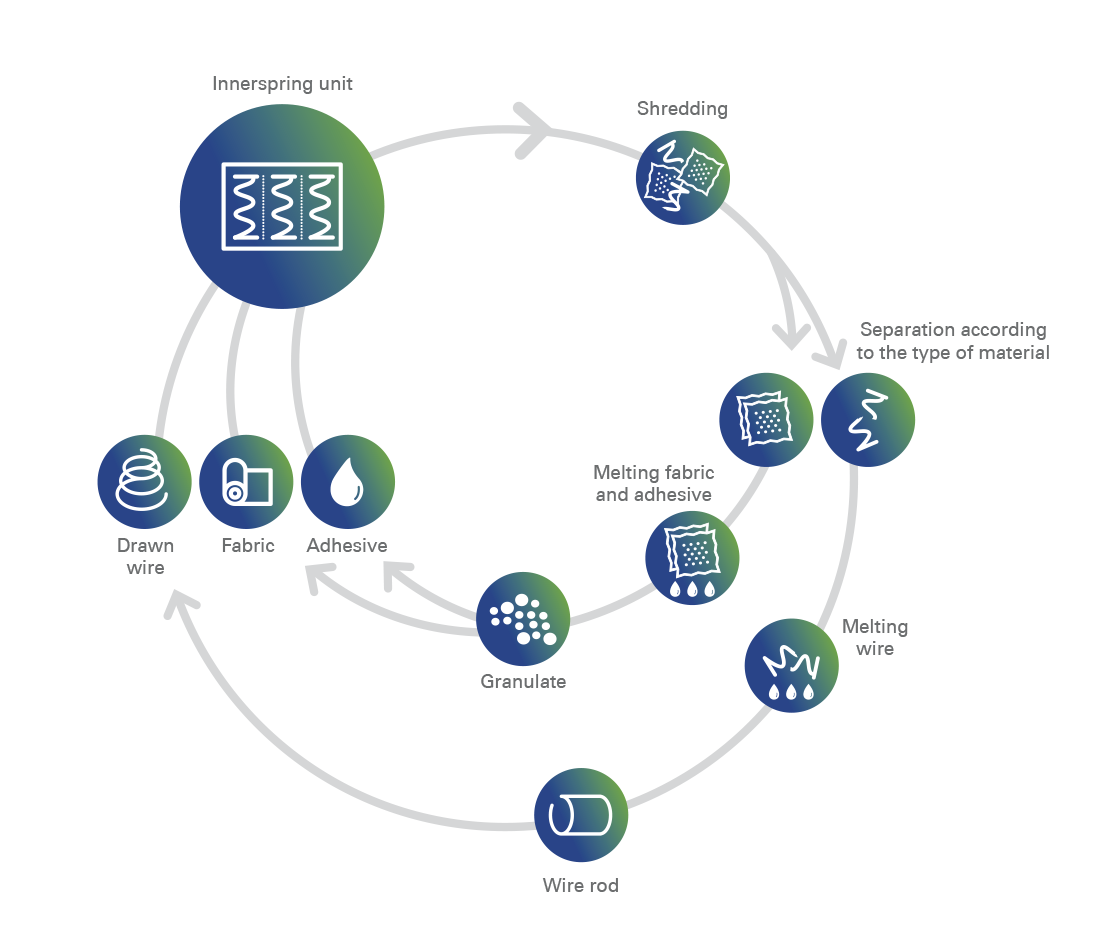

The ever-increasing waste problem, finite resources and growing legislative demands are causing a need for us all to re-think. This means not only to actively promote recycling processes but also to think and work in continuous cycles to support an environment that is worth living in, now and in the future.

As a manufacturer of innersprings, AGRO has a product that has the best prerequisites in terms of sustainability. Over the past two decades, we have built up an extensive know-how in the recycling of our products. Every single one of our products can be recycled and we set a good example by recycling, using our own recycling machine, any innersprings that do not meet our exacting quality standards.

But this is no longer enough for us. As a pioneer in our business we develop solutions of the highest quality that make circular processing possible for all types of innersprings. We are motivated by the idea of creating the conditions that allow a new innerspring unit to be made from used ones – with no loss of quality. This is how ‘sleeping comfort of the next generation’ is created – in the truest sense.

NEW: 100 % Circular

We are proud to announce that in June 2022, a huge step is taken: From now on, our AGRO portfolio produced at the Bad Essen site is 100% circular. All of our pocket innersprings are following the AGRO Uni design. You have the choice of developing your circular innerspring mattress with both PES or PP based material. Simultaneously, we are already able to offer you the first pocket innerspring made from recycled fabric.

We are convinced we have a responsibility to take this step towards the circular economy – and would like to motivate our customers to join us.

Let‘s work together to make the sleep sector sustainable!

A.NEXT Uni – Pocket PES

Adhesive and fabric unified

- Fully C2C ready pocket innerspring – a milestone in innerspring development

- Three components, two circles: fabric and adhesive are both polyester based and can – after separation from wire – be melted and reused without further separation

- The PES technology is available for selected pocket innersprings of the AGRO portfolio

The perfect basis for your state-of-the-art ‘next-generation pocket innerspring mattress’

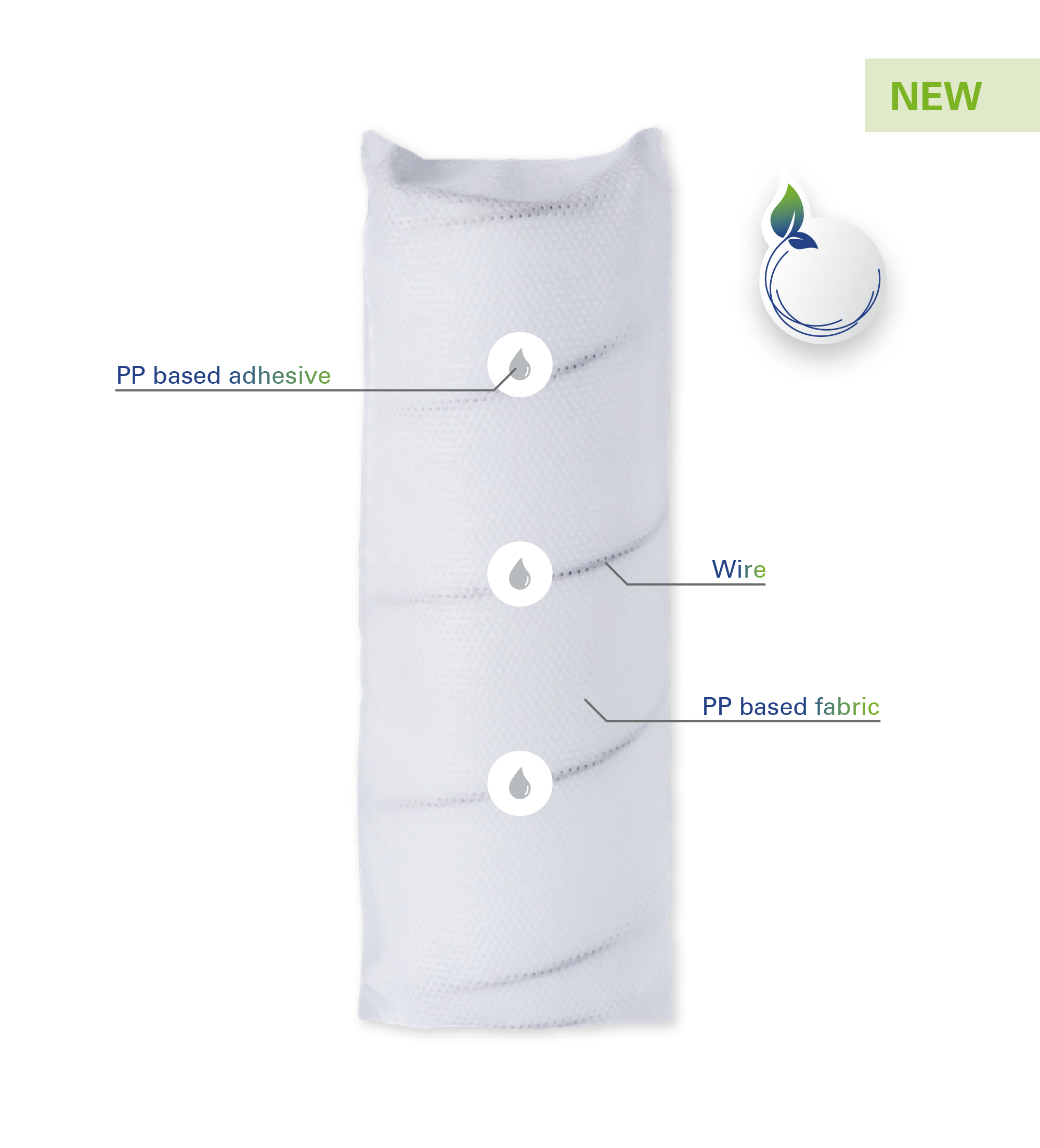

A.NEXT Uni – Pocket PP

Adhesive and fabric unified – part two

-

Circular pocket innerspring based on conventional PP fabric technology in combination with innovative PP based adhesive

-

Three components, two circles: fabric and adhesive are both PP based and can – after separation from wire – be melted and reused without further separation

The circular solution for the high volume market

A.NEXT Arise

With recycled fabric

- The first pocket innerspring based on recycled PP fabric – reducing CO2 emissions per kg by 70% compared to virgin material (Manufacturer‘s estimate)

-

Three components, two circles: fabric and adhesive are both PP based and can – after separation from wire – be melted and reused without further separation

-

The Arise technology is available for selected pocket innersprings of the AGRO portfolio

The eye-catcher with added sustainability

A.NEXT Pure – Bonnell and LFK

Simple and good

- Maximum stability and air permeability combined with a low amount of resources needed

- One component, one cycle: The wire is shredded and melted – new wire can be produced

The classic and proven ‘green solution’

Thinking in cycles with our

A.NEXT innersprings

Separate, process and reuse on the same level